Design and engineering of various mineral processing projects

Engineering Design Departments:

Mineral Processing department:

- Carrying out technological tests

- Laboratory tests design, using test design software

- Proposing plant flowsheet based on laboratory results

- Preparing mass balance based on laboratory tests results

- Main equipment selection

- Process plant reagent consumption optimization and checking the cost control

- Preparing plant facilities requirements

- Plant general layout and general arrangement

- Existing plants troubleshooting, capacity and recovery improvement

- Equipment sizing calculation and material selection

- Preparing process piping and instrumentation diagram ( P&I Diagram)

- Preparing plant process operation manual

- Equipment arrangement and installation supervision

- Preparing plant for pre-commissioning and commissioning

- Operators training

Mechanical Engineering Department (Equipment, Piping, Facilities and Safety)

The services provided in this Department can be summarized as follows:

- Cooperation with the process and electricity department to perform sizing calculations and equipment selection

- Preparing Mechanical Design Criteria and piping Design Criteria

- Mechanical and piping material selection

- Document Preparation for equipment specifications and datasheet

- Preparing the necessary documents to inquire, including PMR, MR

- Preparing HVAC Design Criteria

- Equipment supplier document review

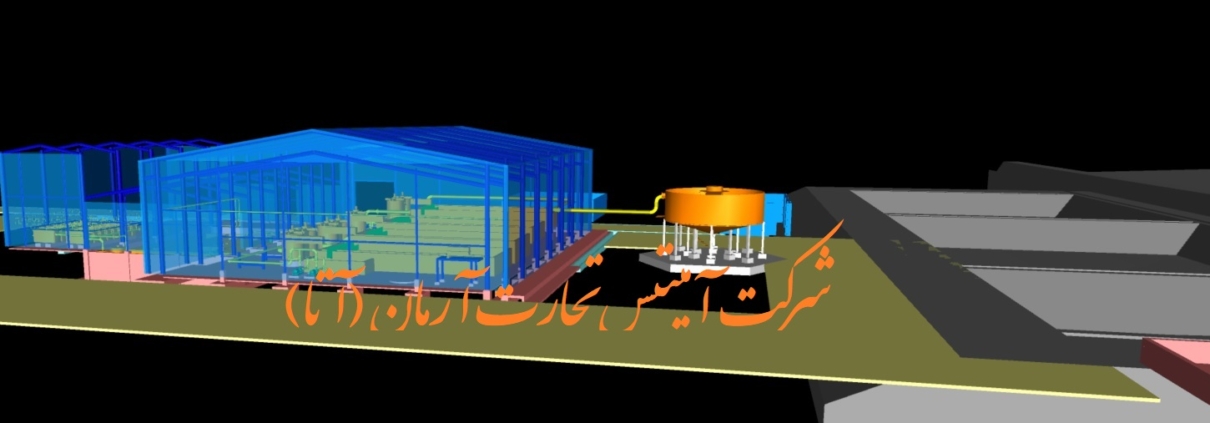

- Performing plant 3d drawings by SOLID WORKS / PDMS software

- Cooperation with the process and electricity department regarding the preparation of documents and layouts of factory equipment according to the experiences of similar projects

- Pipe sizing and material selection

- Equipment installation supervision

- Piping installation supervision

- Maintenance manual preparation

- Plant pre-commissioning, commissioning

- Plants audition and troubleshooting

Civil and Structure Engineering Department

This department provided services can be summarized as follows:

- Review and compile documents for CIVIL and Structure design basics

- Preparing civil and structural Design Criteria based on the geographical area, earthquake zone, climate and national building regulations and international standards

- Concrete and structural modeling for production buildings, and industrial facilities, offices and administrative building

- Providing construction plans

- Providing all required drawings for building and equipment foundation

- Providing MTO for all construction activities

- Construction supervision

- Checking construction cost and comparing to the project plan

- Checking required spare parts

- Checking equipment consumables

Electrical Engineering Department

A summary of the capabilities of this section includes:

- Preparation of Electrical design Criteria

- Preparation of electrical power calculation

- Electrical motors selection

- Electrical Single Line Diagram

- Cable calculation

- Preparing Electrical consumer list

- Electrical panels Single line diagram

- Design and calculations regarding the selection of LV and MV cables

- Engineering studies for plant electrical networks

- Conducting short circuit network studies

- Perform relay calculations

- Lighting design and calculations

- Preparation and design of single line drawings of electrical panels at different voltage levels.

- Installation supervision of all LV drives and motors

- Advice on LV drives and motors

- Prepare Spare Part for drives and motors

- Design, calculation, implementation and testing of ground and lightning systems in accordance with valid standards

- Design, calculation and implementation of capacitive bank, battery and charger

- Calculations and selection of diesel generators

Control and Instrumentation Engineering Department

A summary of the capabilities and services of the control and instrumentation department is as follows:

- Design and consulting in the selection of automation systems

- Preparation and presentation of Design Instrumentation and Control Design Criteria

- Selection of sensors and instruments for measuring pressure, temperature, flow, level, density, analyzer and types of instrumentation converters based on the type of use and process used

- Cooperation with process and mechanical engineering departments to complete P & I Diagram

- Design and selection of industrial PLCs in different sizes and types according to the specific conditions of each project

- Design and selection of HMI software based on process needs